Mixon

Mixon

Mixon provide effective gluing solution from Sweden that, mixing two components glue and hardener. Installation in Japan is over 100 units , and it is highly assessed as a stable mixing technology in Japanese market.

Glue and hardener are mixed in a static mixer. Accuracy of dosage is maintained within the limits set by the control authority, and manual dosage control can be carried out by test weighting the glue and hardener.

Hydraulic pump unit enable to feed high viscosity glue and hardener stably with controlled high pressure.

Matrix application is a method where the tool applying glue has been formed in the same way as the surface to be coated with glue.

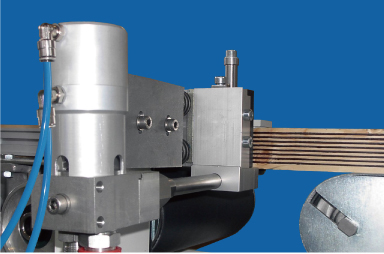

The Mixon matrix applicator is a complete device which transfers the glue to the cut-off surface of the wood under pressure and with controlled dosage and amount of glue, thus saving glue and providing good conditions for strong bonding.

The glue application opening time is controlled by an automatic valve fitted to the glue matrix. In this way reaction is optimized at the same time as any excess glue can be minimized at the start and end of the gluing sequence.

The equipment can be flushed normally without disassembly during daily cleaning maintenance.

Water consumption on flushing may vary with different types of glue, but is always extremely low in comparison with conventional methods.

The application matrix can be dismantled with simple movements for more comprehensive cleaning. Where detergents are used the equipment is fitted with a detergent pump.

When producing goods with glue where a high temperature has a deleterious effect on the working life of the glue and complicates production, additional equipment is available to cool the glue with a simpler and more comprehensive procedure.

Offering optimum glue solution considering with not only the machine, but also the type of glue, environment, and all other situation for each single customer.

MOVIE

TEL:+81-82-277-5775

FAX:+81-82-278-3143